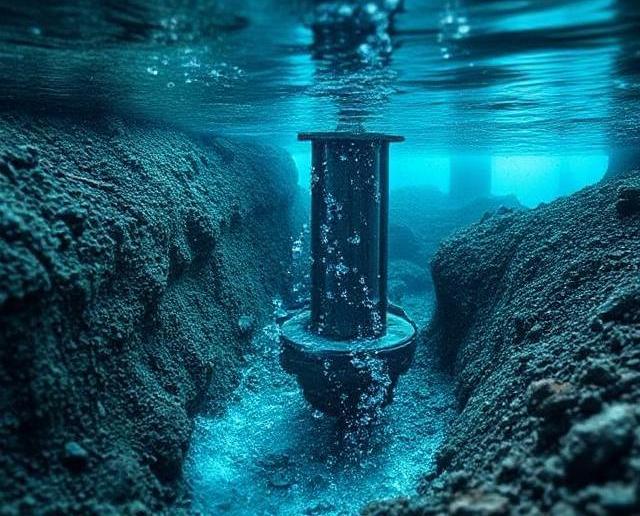

Submersible dewatering pumps play a crucial role in various construction and industrial settings, providing efficient and reliable solutions for removing excess water. These pumps are designed to operate underwater, making them ideal for applications where water needs to be removed from below ground level. This article explores the advantages and disadvantages of submersible dewatering pumps and their diverse applications.

Advantages of Submersible Dewatering Pumps

1. Efficient Water Removal Submersible dewatering pumps are highly effective at removing water from excavations, basements, and other areas prone to flooding. Their ability to operate underwater allows them to pump water directly from the source, reducing the risk of overflow and damage. This efficiency is particularly important in construction sites where water accumulation can delay work and compromise safety.

2. Compact and Portable Design These pumps are typically compact and lightweight, making them easy to transport and install. Their small size allows them to fit into tight spaces, such as narrow trenches or confined basements, where larger pumps would be impractical. This portability makes submersible dewatering pumps versatile and suitable for a wide range of applications.

3. Low Noise Operation Submersible dewatering pumps operate relatively quietly compared to other types of pumps. This is especially beneficial in residential areas or during nighttime operations where noise levels need to be lessd. The reduced noise pollution helps maintain a more pleasant working environment and lesss disturbances to nearby residents.

Disadvantages of Submersible Dewatering Pumps

1. Limited Capacity While submersible dewatering pumps are efficient for their size, they generally have a lower pumping capacity compared to larger, more powerful pumps. This means they may not be suitable for large - scale dewatering operations where high - volume water removal is required. In such cases, multiple pumps or larger - capacity pumps may be necessary.

2. Maintenance Requirements Submersible dewatering pumps require regular maintenance to ensure ideal performance and longevity. They are often exposed to harsh conditions and can be prone to wear and tear. Regular inspection and servicing are necessary to prevent clogging, corrosion, and other issues that can affect the pump's efficiency. Proper maintenance is essential to avoid costly repairs and downtime.

Applications of Submersible Dewatering Pumps

1. Construction Sites Submersible dewatering pumps are widely used in construction projects to remove water from excavations, trenches, and basements. They help maintain dry working conditions, prevent water - related hazards, and ensure that construction work can proceed efficiently. These pumps are essential for managing water during the excavation phase and for preventing flooding in basements and other below - ground areas.

2. Industrial Facilities In industrial settings, submersible dewatering pumps are used to remove water from sumps, tanks, and other areas where water accumulation can cause problems. They are particularly useful in industries such as mining, manufacturing, and wastewater treatment, where water management is critical for operational efficiency and safety.

Conclusion

Submersible dewatering pumps are a vital tool in modern construction and industrial applications, offering efficient and reliable solutions for removing excess water. Their compact design, low - noise operation, and ability to operate underwater make them highly versatile and suitable for a wide range of applications.

English

English русский

русский عربى

عربى